The IEC TS 62446 is a standard related to the inspection and maintenance of photovoltaic systems, which due to its extension was divided into three documents. In this case, it is the third document that is focused on thermographic (infrared) inspection procedures, covering diagnostics also in cables, contacts, inverters, batteries and other elements that make up a photovoltaic system. The tests suggested in this standard are for systems in operation under natural conditions and are performed with two levels of complexity: Simplified Inspection and Detailed Inspection and Analysis.

Requirements for Inspection Equipment

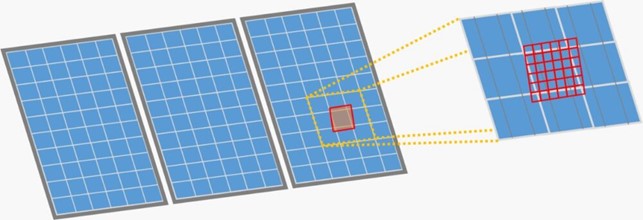

Infrared cameras should measure in a range between -20 and 120 °C, with a resolution greater than 320 x 240 pixels. The minimum geometric resolution should cover a size of 5 x 5 pixels for each cell (Figure 1). Among other specifications better detailed in the standard.

Cameras should be used to photograph the same as infrared cameras, in this way you will have more details of the elements and areas evaluated. Therefore, for cameras, a resolution higher than 9 MPix is recommended.

For proper inspections, other environmental variables must be obtained with the necessary instruments; these variables are: solar irradiance (with pyranometer), air temperature (environmental sensors or thermometers), wind speed (with anemometer), clouds and degree of dirt of the solar panels (both can be evaluated by photographs), current of the panels and DC circuits (with DC ammeter).

Figure 1. Minimum geometric resolution per cell for thermal imaging.

Thermographic Inspection Procedure

It is recommended to first make a visual inspection of the system under study as recommended in [3, 4], in order to clear of severe dirt such as bird droppings, leaves and vegetation and other debris [5], as well as burnt spots that can be easily identified. Pictures before and after cleaning will help during the analysis.

In the same way, climatic variations must be considered, since these could affect the measurements at the time of the inspection. The irradiance should be greater than 600 W/m2 with a current generated by each panel that is at least greater than 30% of the Isc (data that comes on the panel plate or in its technical sheet). The wind should be less than 28 km/h and the cloud cover should be less than 2 on the “octa” scale [6].

Thermographic inspections are suggested at least every four years, for which the photovoltaic system must be connected and generating on a regular basis. The inspection requires 2 people for safety, of which at least one must know the system under test in detail and someone must have knowledge about photovoltaic systems in general. Diagrams, drawings and, if possible, data sheets of the equipment should be reviewed beforehand. Depending on the country or area, certain laws and restrictions may apply when using drones and cameras, so this should be taken into account [7, 8].

Imaging Procedure

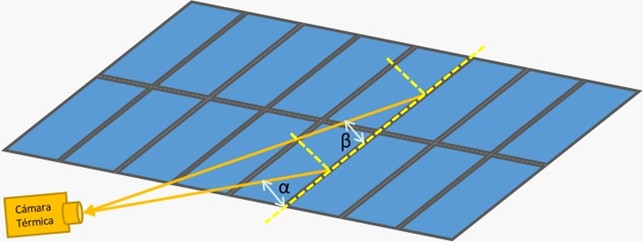

Images should be taken at a minimum distance of 10m, at which distance the minimum resolution suggested for the thermal imaging camera must be complied with. The shots should be taken as perpendicular as possible (failing that, this angle should be greater than 30° as shown in image 2) and avoiding the reflection of the sun, clouds, trees and other elements such as the personnel or equipment that take the images. While the images are being taken, a record of the currents (measured in direct current) generated by the system should be kept.

Figure 2. Angle of view of the thermal camera, where it must be observed that β > 30°.

The levels of detail in the inspection will depend on the type of inspection being performed:

Simplified inspection. Limited review that can be carried out by personnel with little knowledge and focuses mainly on evaluating the basic operation of all elements of the photovoltaic system. Conclusions regarding the quality of each module are not possible. Absolute temperatures are not determined, so thermal patterns are used to assess anomalies.

Detailed inspection and analysis. Reviews can be lengthy or even periodic, measurements are more detailed on each element, and more specific signatures are often sought in order to find problems in the systems. Detailed analyses are carried out of the points with anomalies found during the thermographic review. Absolute temperature measurements are determined. It is carried out by personnel with in-depth knowledge of photovoltaic systems and thermography specialists.

Use of drones for image taking.

With today’s technological advancements, using autonomous or remotely driven vehicles to carry cameras and other instruments is already a cost-effective solution that makes inspection easier and can even automate it. The accompaniment of technologies such as GPS and other references helps to know perfectly where the photographs and other measurements were taken. However, it should be considered that the travel speed and operating distance of vehicles such as aerial drones may interfere with the resolution and response speed of cameras and other sensors, so for fine details the vehicles will be insufficient. Therefore, they should be used to make a general and rapid inspection of the studied park, using the images they obtain as a reference, to later detail with photographs and local measurements at the points where special attention is required.

Figure 3. Aerial Thermography with Drone.

References:

[1] IEC 62446-1, Photovoltaic (PV) systems – Requirements for testing, documentation, and maintenance – Part 1: Grid connected systems – Documentation, commissioning tests and inspection.

[2] IEC 62446-2, Photovoltaic (PV) systems – Requirements for testing, documentation, and maintenance – Part 2: Grid connected photovoltaic (PV) systems – Maintenance of PV systems 1.

[3] IEC 61215-1, Terrestrial photovoltaic (PV) modules – Design qualification and type approval – Part 1: Test requirements.

[4] IEC 61730-2, Photovoltaic (PV) module safety qualification –Part 1: Requirements for testing.

[5] IEC 61724-1, Photovoltaic system performance – Part 1: Monitoring.

[6] 15469:2004, Spatial distribution of skylight – CIE standard general sky.

[7] EN 50110-1, Operation of electrical installations – Part 1: General requirements.

[8] DGUV BGV/GUV-V A3 E, Accident prevention regulations, Electrical installations, and equipment.